This week’s question comes from Rick H. in Iowa: Question: How can I tell what the maximum supported amperage capacity is for your cables?

Answer: Thank you for the excellent question Rick! Understanding the voltage and current limits of your cable(s) is absolutely critical to maintaining a safe transfer of electrical power between your devices. All cables feature some degree of resistance to electrical energy. When electricity is forced to flow up against this resistance, it releases energy into the environment in the form of heat. When cables are very thin, i.e. 30 AWG or smaller, the cabling cannot dissipate that heat energy into the environment fast enough, leading to a fundamental breakdown (failure).

The electrical breakdown of a cable assembly is not a pretty sight. During my younger years when my electronics expertise was in its infancy, I once made the horrible mistake of wiring a 12V DC switch incorrectly on a project box. The switch connected a 12V lawn mower battery to a radio transmitter.

Upon engaging the mis-wired switch, the connection created a short circuit between the negative and positive terminals of the battery — effectively dumping up to 100 Amps of current down some 18 AWG wire. I watched in horror as the wire literally melted from the inside out, causing a flash-fire with the PVC wire insulation melting away like candle wax! The melted wire dripped onto the carpet and nearly started a house fire.

|

| Example: Electric Blanket Fire |

Fortunately, I was able to disengage the switch quickly before things got even worse, but literally in a matter of seconds, significant damage was done. I learned a hard lesson that day about just how important current-handling capacity can be when it comes to cables. What would happen if a whole bundle of wires ignited and went unnoticed? Besides the fire risk, the burning PVC insulation contains toxic fumes that can prove deadly in their own right.

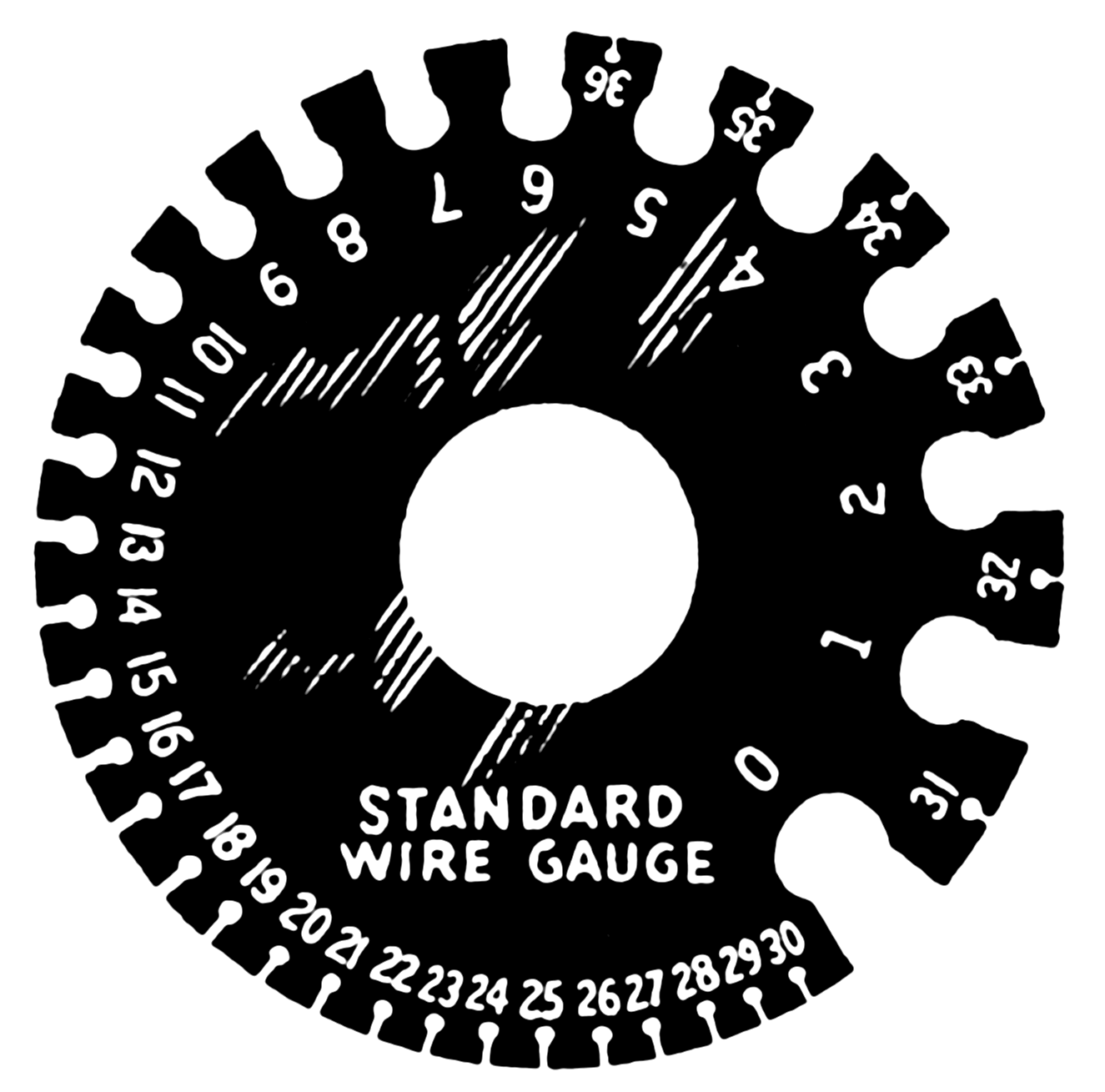

To prevent disaster, you should always select a cable based on the most conservative of safety ratings in mind. The extra margin of error can be a life-saver. So what do you need to know first? #1: You Must Know the Wire Gauge (AWG) of the Cable! This value is imperative. Here at CablesOnDemand.com, we always try to list the wire AWG of our cable assemblies somewhere in the Product Features (Bullets) section on each product detail page.

Our popular D-Sub Cables for instance tend to use 26 AWG insulated wire in their designs. They are often used in custom projects and fed with a variety of both power and signal data. Our CAT5e & CAT6 Ethernet Cables both use 24-AWG wire and our CAT6a & CAT8 Cables both use 26-AWG wire. Our Slim (Thin-Line) CAT6 & Slim CAT6a both feature 28-AWG wire designs. For reference, 28-AWG Ethernet Cables are the thinnest available that are TIA/EIA certified to be safely used for Power over Ethernet (PoE) applications up to Power Class 4 (60W).

#2: Is the Wire Bundled or out in the Open Air?

This, believe it or not, makes a huge difference. When a wire is stand-alone and exposed to the open air, the movement of air around the cable will help cool it down, thus allowing for the transfer of more current.

When a wire is alone and exposed in free-air, we refer to it as: Chassis Wiring

When a wire is bundled together with other wires, we call it: Power Transmission Wiring. Chassis wiring refers to the wiring often found inside the chassis of an electronic device where you may have one wire in free-air that jumps from a connector on the outside of the chassis to a connector or PC board on the inside. Again, because it is in open air, it can handle more current for its given size. Power transmission wiring refers to any wiring that is bundled together.

This is the figure you generally need to worry about most as most of the cable assemblies we make at Cables on Demand feature more than one wire bundled together. Note: This rule applies to all bundled cable types, even those you would normally associate with data transfer and not power. As an example, if you were to open up a typical outdoor rated power extension cord, it would have three wires bundled together (hot, neutral and ground). Since they are bundled and sealed off in a cable jacket, less current can flow through them safely.

The Current Handling vs. Wire AWG Chart: The chart below will tell you the maximum recommended current handling capacity (Amps) for a given wire gauge in both Chassis Wiring and Power Transmission Wiring versions. Remember to choose the Power Transmission Wiring value for most cables purchased through us and other cable vendors (bundled wire). Cables like D-Subminiature (D-Sub) and Ethernet (RJ45) Cables are often used to power devices (i.e. Power over Ethernet PoE) and are considered Power Transmission (Bundled) Wire.

Amphenol Cables on Demand (www.CablesOnDemand.com) sincerely hopes this information proves useful for you and your electronics endeavors! If you have any more questions, please call us toll-free at 1-866-223-2860 or send an e-mail to: support@cablesondemand.com.

Sincerely,

“The Cable Guy“

Product Marketing Manager

Amphenol Cables on Demand

Nick "The Cable Guy" Blas has enjoyed a fulfilling career as Amphenol Cables on Demand's exclusive Product Manager and resident tech expert, having worked for the company just months after its debut launch in December of 2006. Prior to Amphenol, Mr. Blas worked for another interconnect giant, Deutsch Connectors (Now Tyco), in their Defense and Aerospace division as their youngest Program Manager at just 25. While in college for Electrical Engineering and Business Administration/Information Management at UC Riverside and Cal State San Bernardino, Mr. Blas excelled in retail marketing management and sales for Canon USA and Hewlett Packard, both in their printer and imaging business units. Mr. Blas has been a self-professed "tech nerd" since age 10, with a particular fascination with radio and broadcast communications and antenna systems, which led to his college grant work for TRW Corp. Mr. Blas earned his Executive MBA at California State University, Monterey in 2012. He and his wife, Shelly and son, Ethan, currently reside in the stunning Ozark mountains, just outside of Bentonville, Arkansas (home of the world's largest company, Wal-Mart).